plug flow reactor example problem

Full PDF Package Download Full PDF Package. The molar flow of A is F A kmolh and conversion is X.

One Dimensional Pseudo Homogeneous Plug Flow Reactor Model Download Scientific Diagram

CSTR is an idealized flow reactor such that all the contents inside the reactor are well mixed just as in a batch reactor.

. Chapter 1 provides an overview of the problem assignment to make styrene monomer from methanol and toluene. This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures. The plug flow model has many practical applications.

A test platform right next to the reactor core. One can observe that the reactor. Problem c Aspen RCSTR reactor model is used with heat duty set to 0 ie adiabatic and reaction model ISOMER.

Natural circulation is an important design feature and ultimate heat removal mechanism. Now we can write a component mole balance for A. 35 Full PDFs related to this paper.

This is an exothermic reaction having heat of reaction -Hr kcalkmol. Dutch researchers have developed a plan to place what would one could call a miniature-reactor on that platform which allows. This idealization makes the flow reactor analysis simplified extremely as now one can treat the whole reactor as one simple unit or black box Fig.

The exact conservation law used in the analysis of the system depends on the. The specific problem simulated is the partial oxidation of methane over a platinum catalyst in a packed bed reactor. The sodium-cooled fast reactor SFR Gen IV system is considered to be the design with the greatest maturity for the burning of minor actinides MA because fast spectrum neutrons generally have a greater probability for the fission of MA than thermal.

Above is the design equation for a plug-flow reactor to solve this we need to know the rate of reaction -r A. After trip of all RCPs. Elements of Chemical Reactor Engineering_4th Soution Manual-Foglerpdf.

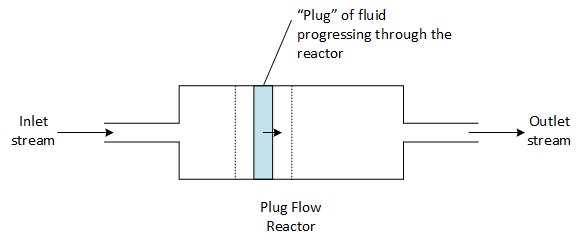

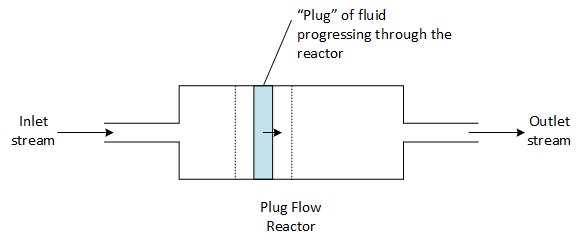

In the first call to the function we only define the argument a which is a mandatory positional argumentIn the second call we define a and n in the order they are defined in the functionFinally in the third call we define a as a positional argument and n as a keyword argument. Essentially no back mixing is assumed with plugs of fluid passing through the reactor. If all of the arguments are optional we can even call the function with no arguments.

It can stir all kinds of chemical material in high temperature high pressure vacuum condition to enhance the mass transfer and heat transfer process. Malcolm Joyce in Nuclear Engineering 2018. A short summary of this paper.

Stainless steel high pressure reactor is an stirring reactor for chemical material reactor with different phase such as gas-liquid liquid-liquid liquid-solid or gas-liquid-solid etc. A mass balance also called a material balance is an application of conservation of mass to the analysis of physical systems. Another type of reactor used in industrial processes is the plug flow reactor PFR.

Flow oscillations can be a problem during natural circulation operations eg. 1173 Sodium-Cooled Fast Reactor. This example solves a plug flow reactor problem where the chemistry is surface chemistry.

This High Flux Reactor HFR has a facility that offers a unique opportunity. Consider the following first-order irreversible reaction taking place in an adiabatic CSTR. Problem b Profiles for the molar compositions of C4H10 and IC4H10 and the PFR reactor temperature are given below.

Chapter 2 presents ten tutorials to introduce the student to the HYSYS simulation softwaretutorial conventions HYSYS interface simulation file creation heater operation conversion reactor process flow diagram PDF manipulation. This severely reduces the thermal limit and the power density along the length of the reactor core. As a fast reactor the SFR appeals to the Gen IV.

To start the simulation initial value of 3 m 3 is assumed. One example is in the design of chemical reactors. Like the CSTRs a constant flow of reactants and products.

That gives reactor volume of 322 m 3. Because of the low flow rates are present coolant. Other simplifications used are.

By accounting for material entering and leaving a system mass flows can be identified which might have been unknown or difficult to measure without this technique. 58 shows a schematic of a CSTR. TextA oversetklongrightarrow textB textC tag251.

Concentration Profile For A Continuously Fed Plug Flow Reactor Download Scientific Diagram

A Front View Of The Plug Flow Reactor And B Surface Area Dimensions Download Scientific Diagram

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

Simulation Of Plug Flow Reactor Pfr In Aspen Hysys Lecture 64 Youtube

A Front View Of The Plug Flow Reactor And B Surface Area Dimensions Download Scientific Diagram

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Isothermal Plug Flow Reactor Part 1 Youtube

Summary Of Mixing And Flow Regimes In Flow Reactors A Radial Versus Download Scientific Diagram

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

Plug Flow Reactor Vapourtec Ltd

Plug Flow Reactor Design Equation Youtube

Plug Flow Reactor Overview Youtube

Mole Balance On A Plug Flow Reactor Youtube

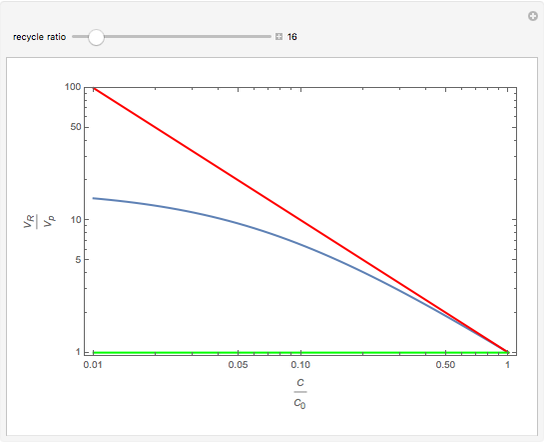

Comparison Of Performance Of Recycle Reactors With Plug Flow Reactors Wolfram Demonstrations Project

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

Matlab In Chemical Engineering At Cmu

Plug Flow Reactor Pfr Mass Balance And Reaction Speed

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium